Our Endeavour is to provide Infinite Precision with Mechanical Vision

Have an Idea for a Design?

Let Zimo Engineering Services lead the way from design to production. Every stage of the mechanical design process, including conceptual design, form/fit/function analysis, layouts, and reverse engineering, is something we can handle.

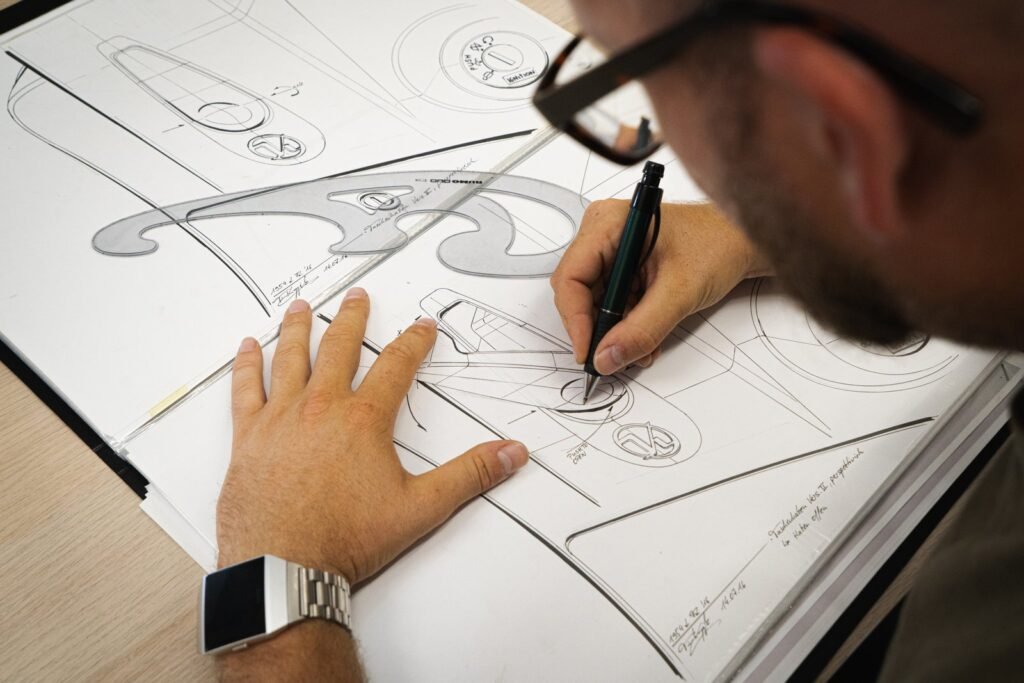

Conceptual design is the inspirational cornerstone. It is when creative exploration by engineers and designers results in novel ideas that are conceptualized to meet project objectives.

Rough sketches and visualizations give stakeholders concrete representations of abstract concepts during this crucial stage.

The implementation of advanced technologies can facilitate collaborative efforts that promote effective communication among team members and stakeholders, ultimately leading to a shared vision.

Functionality Analysis services help companies to make better and more dependable decisions in the long run. Zimo provides functionality analysis services that are essential to making sure software applications and systems operate at peak efficiency and satisfy user expectations and functional requirements. Improving the software’s dependability, performance, and usability is the aim. Services for functionality analysis cover a wide range of topics, such as security, scalability, compatibility, and responsiveness of the user interface.

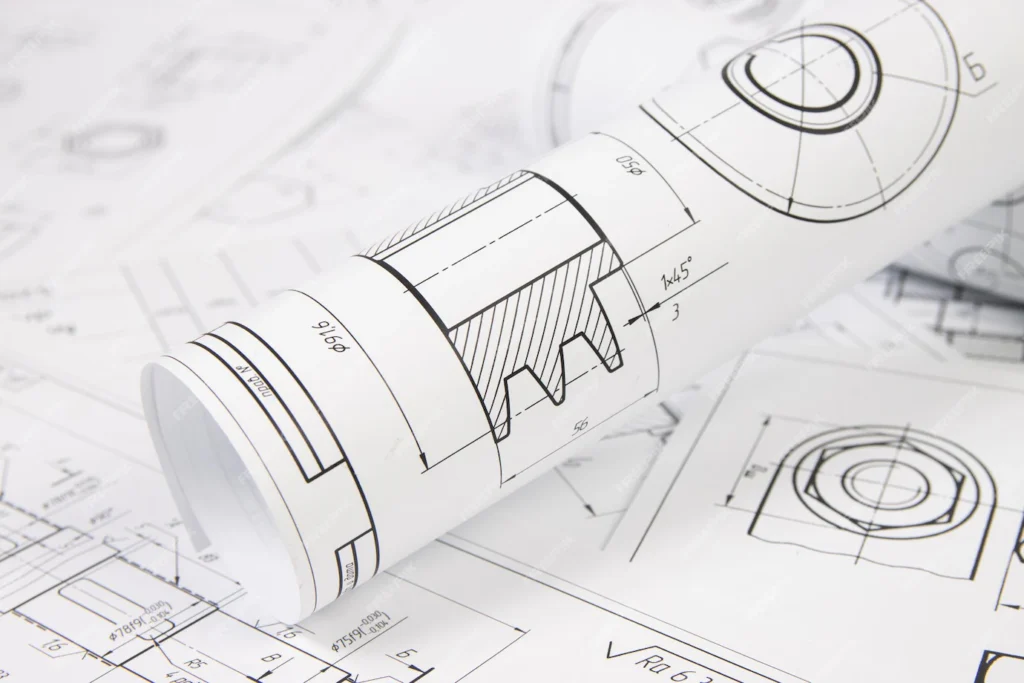

Production drawing services are integral to the manufacturing and product development process. Zimo Professionals provides these essential services. They give the production team a thorough manual by including all necessary information about dimensions, tolerances, materials, and manufacturing procedure. We contribute to smooth manufacturing operations owing to these production drawings, which guarantee that the intended product is turned into a real, high-quality product.

Reverse engineering services are especially helpful for troubleshooting, improving products, and making sure they work with newer technologies. We at Zimo recreate comprehensive models and documentation of the target product using a variety of methods, including software analysis, disassembly, and 3D scanning. We help businesses overcome obstacles relating to outdated parts or undocumented systems, comprehend competitor offerings, adapt, modify, or improve current products generate new ideas, maintain their competitiveness, and make wise choices regarding strategic planning and product development.

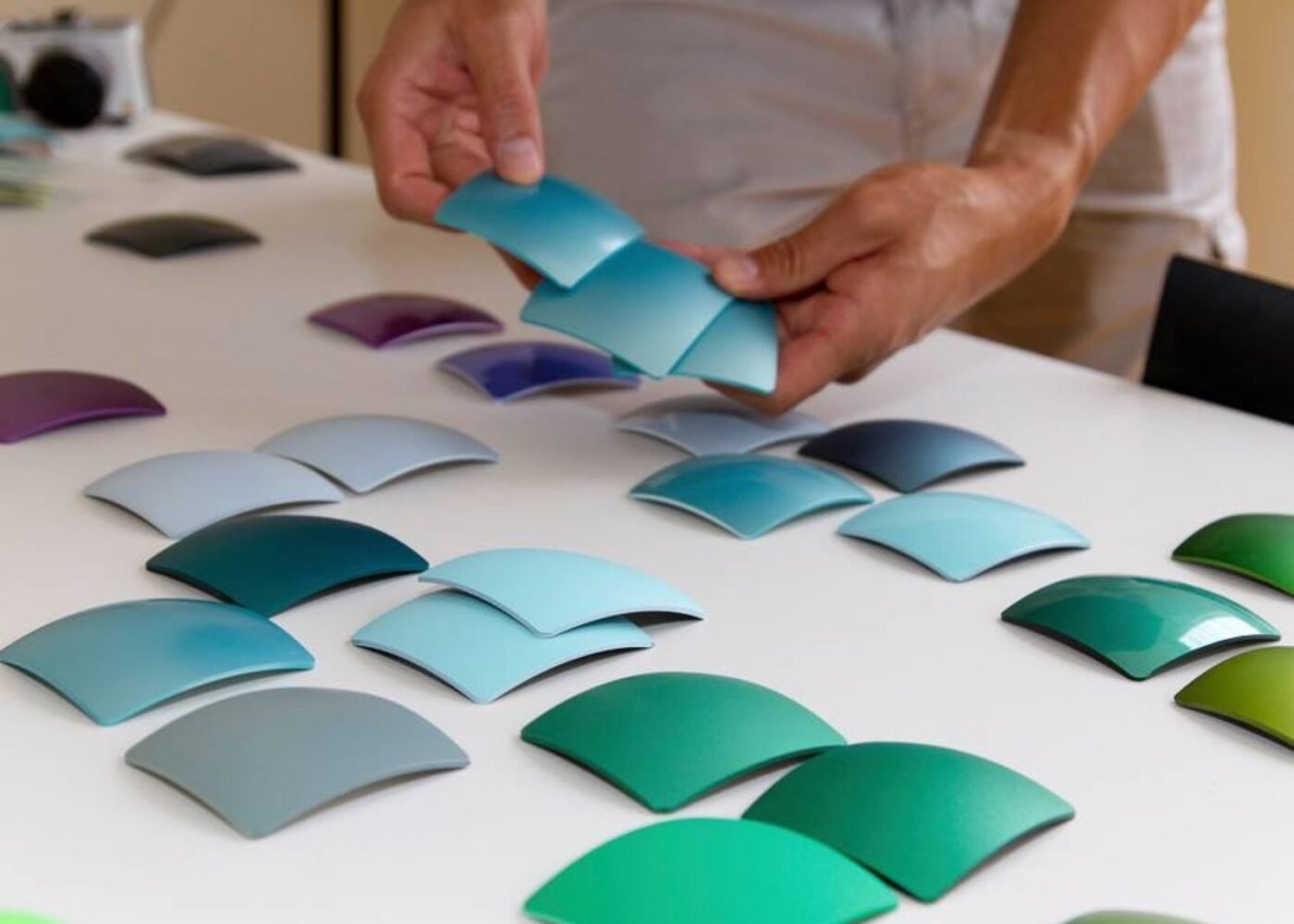

Aesthetic appeal matters. Color, Material, and Finish (CMF) services are widely used in a variety of industries, particularly in design, manufacturing, and product development. These services concentrate on a product’s visual and tactile aspects, making sure that material selections, color schemes, and surface treatments complement the overall design concept and consumer preferences. We choose the right hues, textures, and finishes that satisfy functional specifications while also evoking the right kind of feeling in customers.

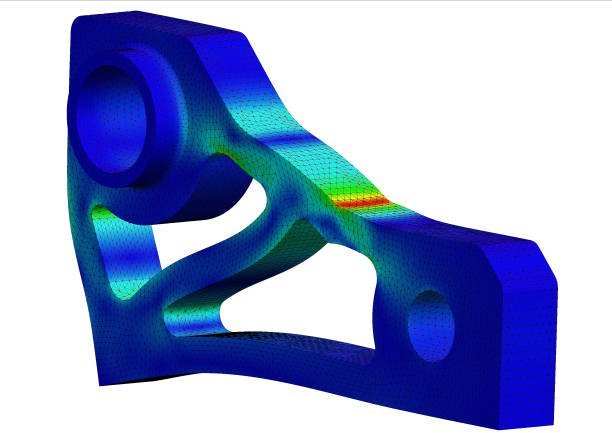

Strength analysis has a prominent role to play in the sphere of mechanical engineering services.

A thorough inspection and assessment of the load-bearing capacity and structural integrity of materials, systems, or components is part of strength analysis services. In strength analysis services we evaluate material properties, stress distribution, and deformation under various loading scenarios using sophisticated engineering tools and simulations, whether they are applied to buildings, bridges, machinery, or industrial equipment. Strength analysis helps to increase the overall dependability and durability of the structure or product.

We Stand out of the Crowd Owing to our Unsurpassed Traits

Frequently asked Questions

A variety of services are provided by mechanical design firms, such as product development, analysis, prototyping, simulation, and 3D modelling.

3D modelling facilitates the visualization, analysis, and virtual prototyping of mechanical components by enabling the creation of realistic and detailed digital representations of those components.

Mechanical design services can reduce material waste, maximize manufacturing efficiency, and identify affordable design alternatives.

Indeed, a large number of mechanical design firms offer scalable and personalized services to meet the demands of small businesses.

Smart technology integration, additive manufacturing (3D printing), sustainable design principles, and a greater focus on user experience are among the trends.

With the aid of simulation, one can anticipate and examine how mechanical systems will behave in various scenarios, facilitating optimization and the detection of possible problems prior to physical prototyping.

Indeed, performance, efficiency, and manufacturability are among the factors that mechanical design services can optimize for product designs.

The choice of material has a significant impact on mechanical design parameters, including strength, durability, and weight. The intended functionality of the design is ensured by the choice of material.