Architecting Dreams, Sketching Success: Zimo wizards make your ideas come alive

Three essential technologies that have a revolutionary effect on engineering and product development are CAD/CAM/CAE services. With the aid of computer-aided design (CAD), intricate digital models can be created, making it easier to visualize and conceptualize systems or products. These digital designs are elevated by Computer-Aided Manufacturing (CAM), which offers instruments for accurate machining and manufacturing procedures. This guarantees a smooth transition between the digital design stage and the actual product realization. In addition, computer-aided engineering, or CAE, uses analyses and simulations to evaluate a design’s structural, thermal, and fluid dynamics aspects. This helps engineers optimize performance and spot possible problems before physical prototyping. When combined, CAD/CAM/CAE services improve productivity, shorten time-to-market, and stimulate innovation throughout the whole product development lifecycle.

Benefits for CAD/CAM/CAE Services

CAD/CAM/CAE services revolutionize engineering workflows and the process of product development, offering numerous advantages to a wide range of industries. Among the principal benefits are:

Increased Output

Through the automation and streamlining of design, manufacturing, and engineering processes, CAD/CAM/CAE services dramatically increase overall productivity by lowering manual labor and minimizing errors.

Creative Design Investigation

Engineers can experiment with different concepts and iterations thanks to CAD, which promotes creative design exploration. This encourages creativity and the creation of original, well-thought-out solutions.

A Quicker Time to Market

The product development lifecycle is accelerated by the smooth integration of CAD, CAM, and CAE, allowing for quicker design iterations, quicker prototyping, and timely market entry.

Economy of Cost

CAD/CAM/CAE services ensure resource optimization and lower production costs by streamlining designs, enhancing manufacturing procedures, and reducing material waste.

Optimization Through Simulations

Engineers can optimize designs for elements like fluid dynamics, thermal performance, and structural integrity thanks to CAE services, which provide comprehensive simulations and analyses. This aids in the early detection and resolution of possible problems during the design stage.

Enhanced Precision in Design

Accurate digital modelling is made possible by CAD tools, which guarantee design accuracy. Then, using extreme precision, CAM services convert these designs into manufacturing procedures, preserving consistency between the digital and physical domains.

Smooth Cooperation

CAD/CAM/CAE tools facilitate the exchange and review of design data centrally, which improves collaboration between interdisciplinary teams. This encourages clear communication and guarantees all stakeholders are on the same page.

Personalization and Customization

The personalization and customization of products is facilitated by CAD/CAM/CAE services, which enable the effective modification of designs to satisfy client requirements and preferences.

Lower Prototyping Expenses

By eliminating the need for large physical prototypes, virtual prototyping with CAD/CAM/CAE services lowers material, manufacturing, and testing costs.

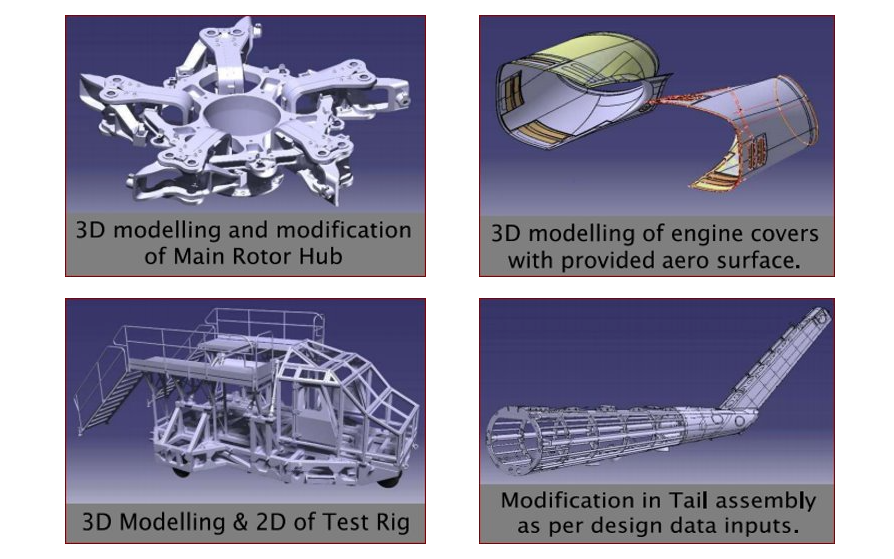

CAD Modeling:

The process of turning abstract concepts into intricate digital representations is facilitated by computer-aided design (CAD) modeling. CAD modeling allows designers to see and examine the dimensions and physical characteristics of objects or systems by creating three-dimensional (3D) virtual models using specialized software. Engineers and architects can simulate real-world conditions, test functionality, and identify possible problems early in the design process thanks to the accuracy and precision of CAD modeling, which improves product development.

CAD Data Conversion

CAD data conversion is an essential procedure that involves converting digital design files from one format to another. Converting CAD data may entail changing the file formats, scaling, rotating, or modifying the geometry to meet the needs of the receiving system. CAD tools aid in smooth communication and cooperation between designers, engineers, and stakeholders. Effective CAD data conversion contributes to improved interoperability, streamlined workflows, and fewer errors.

CAD/CAM/CAE Testing and Simulations

CAD, CAM CAE prove to be a potent toolkit that lets engineers and designers evaluate and test their ideas virtually before building physical prototypes. CAM converts digital models into manufacturing instructions, CAD helps create detailed digital models, and CAE completes the process by rigorously testing and simulating the virtual models. CAD, CAM, and CAE integration not only expedites but also reduces expensive mistakes, improves product quality, and fosters creativity.

Additive Manufacturing Design

Additive Manufacturing (AM) design, commonly known as 3D printing, is an innovative method for developing and producing products. Unmatched flexibility is provided by this creative design process, which makes it possible to produce extremely complex and customized geometries that would be difficult or impossible to produce using traditional manufacturing methods. Additive Manufacturing stimulates creativity by enabling designers to experiment with new forms and complex structures, tailoring parts to particular functions.

Rapid Prototyping

Rapid prototyping’s main objective is to give engineers and designers concrete versions of their ideas so that they can be tested visually, functionally, and through design iterations. Fast prototyping’s efficiency and speed cut down on the time it takes to go from initial concepts to working prototypes, allowing for a more flexible and iterative design process. This method is especially useful for improving and verifying designs and seeing possible problems early in the development cycle.

Prototype Designing

When it comes to product development, prototype design is the first set of instructions for turning ideas into physical objects. Before being produced in large quantities, it signifies the critical stage at which creative concepts take shape and are represented in tangible form. To bridge the gap between concept and reality and to promote efficient collaboration and communication among cross-functional teams, prototype designing is a dynamic and crucial stage in the development cycle.

CAD Data Visualization & Representation

An essential part of the design and engineering process, CAD data visualization and representation creates a visual link between intangible ideas and tangible goods. Engineers and designers can produce accurate digital models of systems and objects by using computer-aided design (CAD) software. These visual aids facilitate the exchange of design concepts, allowing stakeholders and team members to work together to make decisions. The efficiency and accuracy of the design are improved by the capacity to visualize and represent CAD data.

Production/Assembly Drawings

Production and assembly drawings are essential parts of the manufacturing process because they act as comprehensive manuals for converting conceptual designs into physical goods. Both are required for reducing errors, expediting the manufacturing process, and enhancing communication between production teams and design engineers A high-quality product can only be produced efficiently with the use of clear and accurate production and assembly drawings.

Mold Designing and Prototyping

Creating exact blueprints for the molds that will be used to shape materials like composites, metals, and plastics into the desired shapes is the process of designing molds. Since the mold must accurately and consistently replicate the intended design, accuracy is essential in this process. Prototyping is crucial for confirming the general design concept and the mold’s efficacy at the same time. Prototyping is used to create an initial model that is used to assess the product’s viability, functionality, and dimensions.

CFD/Mold Flow Analysis

Computational fluid dynamics (CFD) offers important insights into how gases and liquids behave under different circumstances. Mold Flow analysis expands the capabilities of CFD to simulate the flow of molten material inside a mold cavity in the context of mold design and manufacturing. Engineers can improve the effectiveness and caliber of the injection molding process by utilizing sophisticated simulations.

CAD/CAM Software Customization/Automation:

Through software customization, industries can customize CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) to meet their unique requirements, improving productivity and optimizing workflows. This not only creates an environment that is more intuitive and user-friendly, but it also speeds up the design process by automating tedious tasks. Additionally, the automation of CAM operations, such as machining and tool path generation, minimizes errors and increases overall accuracy.

Crafting Tomorrow's Designs Today: Zimo CAD Services with Excellence.

With futuristic vision and revolutionary thought process you can bring an unexceptional change in your projects. All you need to do is contact Zimo for convincingly top-notch CAD services. Our dedicated team of professionals and experts is dedicated to deliver you the best by providing you Predictability, effectiveness, and the capacity to see and test designs prior to actual production are all provided by CAD services. You can contact us at…… we will be happy to bring about ultramodern technology into your workspace.

Frequently Asked Questions

Predictability, effectiveness, and the capacity to see and test designs before actual production are all provided by CAD services. They cut down on errors, expedite the design process, and lower overall costs.

Product design, architectural planning, mechanical engineering, and electronic circuit design are just a few of the many projects that can benefit from the versatility of CAD services.

CAD software makes it simple to share and collaborate on design files, enabling instantaneous feedback and guaranteeing that everyone in the team is working with the most recent design data.

Indeed, most CAD services come with the ability to draft in two dimensions and model in three, giving users access to a wide range of tools for producing intricate designs from different angles.

Yes, CAD services are flexible and scalable, allowing small businesses and startups to have access to sophisticated design tools without having to make large upfront investments. They can also be tailored to their specific needs and budgets.

Early detection and correction of design flaws by CAD services lowers the possibility of expensive production errors. They also save time and resources by streamlining the design cycle.